________________________________________

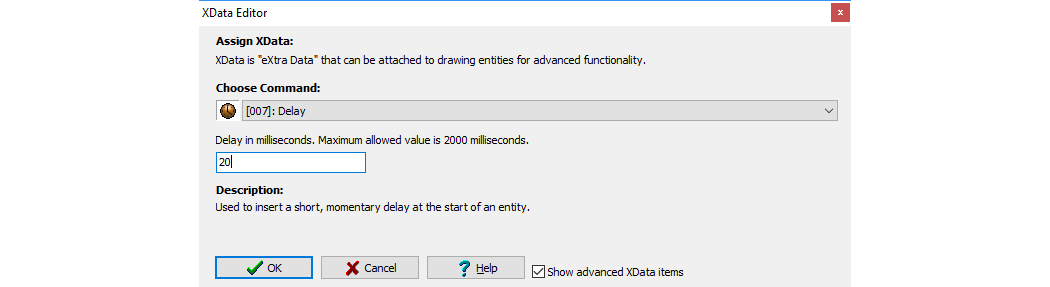

Assign XData functionality to selected drawing entities using the Assign XData pull-down window

XData Contents Overview XData in OMX Files

Be sure to read the XData Overview section for important information and notes concerning XData. Commands marked "[Hidden]" will not appear on the Choose Command drop-down menu unless "Show advanced XData items" is checked:

Some XData items have "Start" in their name. For these, XData is applied for all entities that follow until either the corresponding "End" XData is encountered, or the end of the path is hit. XData items that do not have "Start" in them are applied for the entity only, and do not propagate down the path. Also note that XDatas that "Start" something also have a green colored glyph.

[Number in brackets] represents the code number used to store the XData item in an OMAX OMX file, which is listed here for ease of reference for those writing software to output OMAX OMX files.

[006] – Pause

[007] – Delay

[013] – Force Percent Speed

[014] – Force Absolute Speed

[043] – Force Start Percent Speed

[044] – Force Start Absolute Speed

[019] – Move Z [Requires Motorized Z]

[039] – [Advanced] Set tool offset value

[040] – [Advanced] Modify tool offset amount

[041] – [Advanced] Clear offset overrides

The numbers next to each XData item indicate the code number used to categorize the XData item within the software and OMX file, which is what one would use when generating OMAX files, such as through a post processor or script. (In LAYOUT or MAKE, one would typically ignore these numbers.)

No XData is assigned. This is the default condition for all entities when no other XData item has been assigned.

To remove XData from an entity, simply set its XData to be "No Data".

This Data item allows a comment to display on entities in the LAYOUT drawing or tool path. This can be a useful way to convey a message to another user.

As with any XData item, the user must have XData display enabled in order to see it.

If an entity has "Pause" assigned to it, the controller will come to a full stop precisely at the start of the entity, and it's up to the operator to press "Continue" should they wish to. This is useful as a way to put in a programmed stop point for purposes such as re-fixturing the material.

The pause will occur at the exact location specified (the starting point of the entity with Pause assigned). Compare this with the Insert Pause command in MAKE, which is not exact.

When a Pause occurs, the jet and other relays will shut off, similar to as if the "Pause" button were pressed.

Unlike the “Insert pause point here” command in MAKE, this commanded XData is precise, and will pause at the precise location specified, which is the start of the entity for which this XData item was assigned.Using this command does NOT set the “Path Interrupted Home” at the paused location.

One can insert up to a 2 second delay where the machine will come to a stop, delay the specified amount of time at the start of the entity, and then resume running the path. Delays are limited to a maximum of 2 seconds (2000 milliseconds). Delay time is specified in units of milliseconds (1/1000 of a second).

This command specifies the nominal speed of the entity by percentage of a given speed. It can range from 0.001% to 20000%. Acceleration and deceleration ramps and machine specific speed limits (maximum cutting speed) will still be applied. The command is applied to a single entity.

The percent speed is determined relative to the entity quality type as follows:

Quality 1-5, Minimum Taper: Percentage of Separation Speed

Etch Quality: Percentage of operator entered Etch Speed

Scribe Quality: Percentage of operator entered Scribe Speed

Water-Only Quality: Percentage of operator entered Water-Only Speed

Traverse and Heads-Up-Traverse Quality: Percentage speed overrides are ignored

This command can be useful to help vary etch depths, or for cutting tests, or to more closely match the results of non-OMAX generated OMAX Routed Data file formats that have been imported.

For cutting entities, if the specified speed is greater than the separation speed, in order to provide a more even depth of cut, the accelerations used for corners will be based on the Newtonian constraints of the machine instead of the cutting model constraints, since you are no longer cutting all the way through.

This XData command specifies the maximum speed of an entity. Due to machine acceleration limits, short entities may not reach the commanded speed. If the specified speed is greater than the maximum allowed cutting speed (as defined in Advanced / Administrator Setup), it will run at the maximum cutting speed.

If the specified speed is greater than the maximum allowed machine speed (as defined in Advanced / Administrator Setup), it will run at the maximum machine speed.

Set the speed for the cutting entity to some exact value, overriding whatever MAKE would have otherwise chosen based on cutting models or otherwise. This has no effect on traverses or Heads Up Traverse entities. This can be useful for running experiments, controlling etch depth, etc.

If the specified speed is greater than the separation speed calculated for the given pump, nozzle, and material setup, the accelerations used for corners will be based on the Newtonian constraints of the machine instead of the cutting model constraints, in order to provide a more even depth of cut, since you are no longer fully separating.

Because this overrides key features of the OMAX controller, it is generally not recommended to use this for cutting. Use it instead for specialty purposes such as multi-depth etching or cutting tests.

This XData command specifies the maximum speed of an entity. Due to machine acceleration limits, short entities may not reach the commanded speed.

If the specified speed is greater than the maximum allowed cutting speed (as defined in Advanced / Administrator Setup), it will run at the maximum cutting speed.

If the specified speed is greater than the maximum allowed machine speed (as defined in Advanced / Administrator Setup), it will run at the maximum machine speed.

Parameters: Distance, Speed

Moves the Z-axis the specified distance vertically (with no horizontal motion). Use a positive value to move the Z up (+Z) and a negative value to move the Z down (-Z).

If a speed is not specified or a "0" entered, the speed will remain undefined, and the Z speed will be set to the maximum.

All relays will remain in their present state while the motion is performed, just like for XY motions. On a traverse, the jet will remain OFF and on a cutting entity the jet will remain ON. Moving Z while cutting can cause excessive splash.

Do not use this command in conjunction with the Terrain Follower accessory. Doing so may result in collisions, incompatibilities with the tool path and/or "backup" and "ahead" features, as well as other unwanted behaviors.

Parameters: Tool offset distance

Forces the tool offset to the specified amount. This command can be applied only to leads and traverses.

XDatas are applied at the START of an entity, and for this command, it is a Traverse. Since it applies to the start, it also effects the prior entity because the prior entity must match the desired offset of the entity that you are on. If you have a cut quality entity and then a traverse, and you put this command on the traverse, the preceeding cut will also be affected. It is suggested to use this XData command only when connected to traverses or leads where such modifications will not cause conflicts. If necessary, consider dividing your traverse in half and assign this XData to the second half only.

Parameters: Tool offset distance to add or subtract (if negative)

Modifies the tool offset by the specified amount. This command can be applied only to leads and traverses.

XDatas are applied at the START of an entity, and for this command, it is a Traverse. Since it applies to the start, it also effects the prior entity because the prior entity must match the desired offset of the entity that you are on. If you have a cut quality entity and then a traverse, and you put this command on the traverse, the preceeding cut will also be affected. It is suggested to use this XData command only when connected to traverses or leads where such modifications will not cause conflicts. If necessary, consider dividing your traverse in half and assign this XData to the second half only.

Parameters: None

Removes any changes to the tool offset made by commands [39] and [40].

XDatas are applied at the START of an entity, and for this command, it is a Traverse. Since it applies to the start, it also effects the prior entity because the prior entity must match the desired offset of the entity that you are on. If you have a cut quality entity and then a traverse, and you put this command on the traverse, the preceeding cut will also be affected. It is suggested to use this XData command only when connected to traverses or leads where such modifications will not cause conflicts. If necessary, consider dividing your traverse in half and assign this XData to the second half only.

Parameters: Forced percent line speed, forced percent corner speed

This command specifies the nominal speed of the following entities by percentage of the calculated separation speed. It can range from 0.001% to 20000%. Acceleration and deceleration ramps and machine-specific speed limits (maximum cutting speed) will still be applied. The command is applied to a series of consecutive entities. Assigning zeros will terminate the series.

The first parameter will specify the maximum line speed on the entity. The second parameter will specify the speed at the end of the entity (for example, in corners). If any parameter is set to zero, the series is canceled and the calculated standard speed values will be used. The forced speed will max out at the normal speed limits (maximum cutting speed, maximum machine speed).

The percent speed is determined relative to the entity quality type as follows:

Quality 1-5, Minimum Taper: Percentage of

Etch Quality: Percentage of operator entered Etch Speed

Scribe Quality: Percentage of operator entered Scribe Speed

Water-Only Quality: Percentage of operator entered Water-Only Speed

Traverse and Heads-Up-Traverse Quality: Percentage speed overrides are ignored

This command can be useful to help vary etch depths, for cutting tests, or to more closely match the results of imported non-OMAX-generated OMAX Routed Data (ORD) file formats.

For cutting entities, if the specified percentage is greater than Quality 1 speed, the accelerations used for corners will be based on the Newtonian constraints of the machine instead of the cutting model constraints (including pump, nozzle, material, and quality), since it may no longer be cutting all the way through.

This XData command specifies the maximum speed of an entity. Due to machine acceleration limits, short entities may not reach the commanded speed.

Parameters: Forced absolute line speed, forced absolute corner speed

Set the speeds for the following cutting entities to an exact value, overriding what MAKE otherwise would have selected based on cutting models. This command can be used for running experiments, controlling etch depth, and so on. Assigning zeros for the parameters will terminate the speed override series, and the standard values from MAKE will be used.

Absolute speed overrides will be ignored on traverses and heads-up traverses (HUT).

The first parameter specifies the maximum line speed on the entity. The second parameter will specify the speed at the end of the entity (for example, within corners). The forced absolute speed will max out at the normal speed limits (maximum cutting speed, maximum machine speed).

If the specified speed is greater than the Quality 1 speed calculated for the given pump, nozzle, and material setup, the accelerations used for corners will be based on the Newtonian constraints of the machine instead of the cutting model constraints (including pump, nozzle, material, and quality). This will provide a more even depth of cut, since you are no longer fully separating.

This XData command specifies the maximum speed of an entity. Due to machine acceleration limits, short entities may not reach the commanded speed.