![]()

![]()

________________________________________

During the compilation process, a number of messages can be generated. Some are for information purposes allowing the user to check the path to ensure that the cutting motion had been performed as intended. Some of the messages indicate errors that could prevent the path from being properly compiled. When an error occurs, the compilation process will exit prematurely with no useable cutting path generated.

Compiler Warning:

For information only. Cutting path is fully compiled and can be run.

Compiler Error:

The compilation process was not successful. A cutting path was not generated. Settings and/or geometry of the path have to be modified.

In many cases, the error message may simply pop up in front of the screen to tell you something. In other cases, it may also create a list of one or more messages for your review. This list will display in a special tab in the same area as the drawing statistics. This tab is normally hidden, unless there is something additional to display.

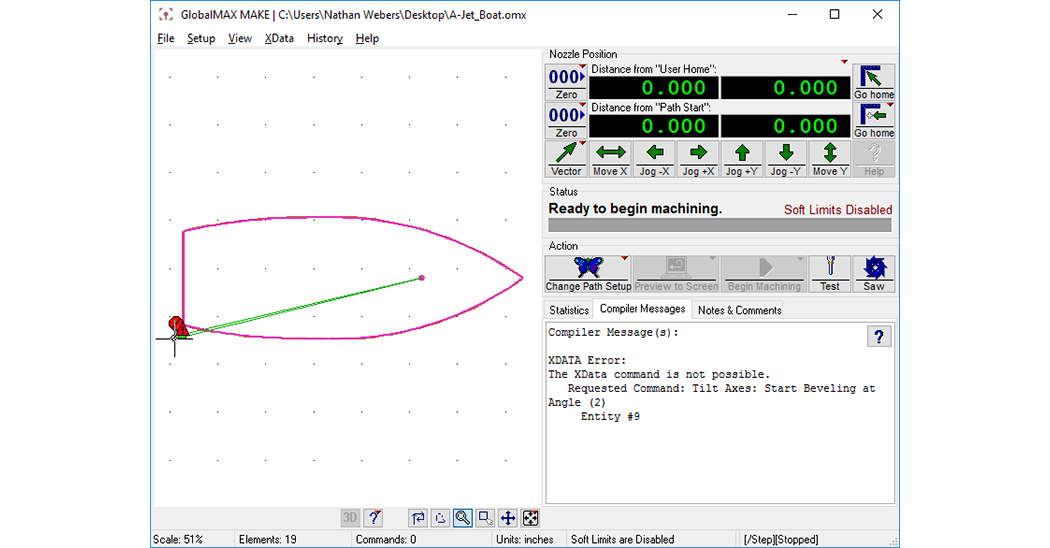

An example of a Compiler Message displayed in MAKE

Sometimes when a warning or error occurs, it can trigger a cascade of errors for entities that follow in the tool path. When diagnosing compiler errors or warnings, it is often useful to look at the first error or warning encountered, as it may be the root cause of additional messages that follow.

Warnings and error messages will show up in the path preview area as red error triangles, or yellow warning triangles.

These triangles will show up in the display only if showing XData icons is enabled. These triangles can help narrow down the source of the message to within the general area of the triangle icon. Typically the source of the error would be the entity the triangle is on, or one of the neighboring entities, though this is not guaranteed.

One may also find the various "Preview" tools useful for diagnosing the source of warnings, though preview will not be available in the case of errors, since the tool path did not fully compile.

Excessive Z slope Error

The Z-axis is commanded to climb too fast for XY motion. The requested largest slope will be displayed in degrees.

This can occur for a variety of reasons. For example, a Z motion on a lead may suddenly become super-steep as the lead is shrunk when optimized. Typically the solution is to re-edit the tool path so that the Z motions are of a less steep slope, or choose a different method of defining the geometry.

Too Small Rotary Part Error

The requested radius of the part is too small for the rotary axis. A cutting path cannot be generated. This message contains the entity number and the requested part radius in inches.

Forced Speed Warning

The forced speed specified in an XData command is outside of the normal cutting range. This may have implications for the cutting result. When the relative speed is above 100%, one must expect that the cut will not separate the part.

This message will display the entity number and the relative speed in percent.

Tilt Speed Warning

During the compilation of the path, the motion speed profile of the A-Jet must be taken into account in addition to the XY cutting speed. At times this causes a reduction in cutting speed. In certain instances, the overall cutting speed can be increased by dividing the entity into several segments and thus incurring the slowdown only during a portion of the cutting path.

This message contains the entity number and either the necessary speed reduction factor or the assigned extra steps per frame (extra commands inserted into the path in order to accommodate the geometry – this information can be ignored). Consider also using "Preview" to identify the slow area.

This message can typically be ignored for a good tool path. The consequence of ignoring the message is the part may be slower than necessary.

Exceeds Tilt Axis Limits Error

One of the axes exceeds its limits. A requested (Tilt-) position cannot be accommodated. The requested angle may be too large for the available hardware, or the necessary hardware may not be enabled in the Path Setup dialog.

When this error occurs, typically one has to either reduce the angle requested in the path, or create additional geometry such as corner passes to allow the full angle to be made.

No Tilt Axis Error

The tool path requires tilting but there are no active tilting axes. They may not be present or not enabled or the Z-axes are disabled

Orientation Warning

At this point, the orientation of the actual tilted jet deviates severely from what it should be to produce the intended geometry. Since the tilting angle is small at this point, the resulting blemish is most likely not very pronounced. The tool path will compile but the user has to make sure that the blemish at this point is acceptable for the application and needs to check the tilt preview to see if the A-Jet motion is acceptable.

Orientation Error

At this point the orientation of the actual tilted jet deviates severely from what it should be to produce the intended geometry. This would lead to a severe blemish on the part, which is not acceptable. The tool path will therefore not compile.

Excess Rotation Error

The A-Jet head is required to exceed its possible rotation. The rotational axis of the A-Jet is limited by its rotation capability. During the compilation process, MAKE attempts to fit every cutting streak into this window; however, there are certain geometries (for example a spiral cut) that exceed the possible A-Jet rotation. In this case it is not possible to generate a cutting path.

To avoid this kind of error, it is a good practice to insert Corner Loops into the cutting path. As the jet is being turned off, it can re-position itself to accommodate the necessary rotation.

This message indicates the number of the last entity of the affected cutting streak and the required minimum and maximum angle of the rotational A-Jet axis

XData Error

The requested XData commands in the OMX file are not possible. This can be due to the selected/enabled hardware configuration (for example, Z-move without motorized Z-axis or rotary commands without the rotary axis). It can also be due to impossible values within the XData command.

XData Warning

Some XData commands may be ignored. XData may be on entities where it cannot be used, or a not-sufficient number of values were being passed. The XData is then ignored.

This message displays the entity number and the available and necessary number of XData values. For example, "2/3" means 2 values found and 3 expected.

Tilting Error

The tool path requires tilting that cannot be accommodated. One reason for this is that the necessary hardware is not enabled or available. The hardware (if available) can be activated in the advanced setup dialog and enabled in the path setup dialog. Another possibility for this error is either a programmed tilting angle is too large, or a compound corner angle exceeds the limits. Even a small bevel can cause large compound angles at very acute corners. The large compound angle can be avoided in many cases by inserting corner loops at outside corners.

This message contains the entity number and the requested angle in degrees

Corner Angle Error

The corner angles of two consecutive entities do not match. In a cutting path, the end corner of one entity must match the start corner of the next entity. This has been violated in this cutting path. The mismatch is larger than the value 'CornerCheckAngle' in makepreferences.ini and will not compile.

This message displays the entity number of the second entity and the angle mismatch in degrees

Corner Bevel Warning

The Corner angles of two consecutive entities do not match. In a cutting path, the end corner of one entity must match the start corner of the next entity. This has been violated in the cutting path. The match is not perfect but below a threshold set as 'CornerCheckAngle' in makepreferences.ini. A warning will be displayed showing the entity number of the second entity and the angle mismatch in degrees.

Delphi Exception Error

Any kind of Delphi Exception that prevents the code from functioning properly. Typically this is a programming error (bug in the software). Please immediately save a tech report and send it to bugs@omax.com. The message will contain location information and a description of the Delphi error message, and the Tech Support Report will give OMAX Developers the information needed to fix it.