![]()

![]()

________________________________________

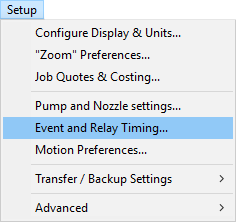

Sets the delays for various events

Use the Event and Relay Timing item on the menu to control how long to wait (in seconds) after certain events occur.

The default values will be different if your GlobalMAX is configured with Dual On/Off valves (as defined in Advanced Setup).

In most cases, the default values will work fine. There are some cases, however, when you may wish to adjust them, to fine tune system performance for your particular needs:

- You are making many parts from a hard material (such as steel).

In this case, you may be able to reduce the delays before moving, as the surface is less susceptible to marring by a jet that has started moving before it was completely shut off.- You are making parts from a very soft material (such as Styrofoam®).

You may want to increase the delay times if enough water is still coming out of the nozzle to mar the material you are working with.- You are making parts with many traverses.

Each time a traverse is reached, the nozzle will turn off, move, and then turn on again. This means that both delay times will be applied. If you have many traverses in your part, this can add up to a considerable amount of time. Again, how much you can decrease the delay (if at all) will depend on the hardness of the material, and whether or not surface marring is important. You will also be working with a trade-off between minimum delays, and maximum protection from nozzle plugs- You are machining brittle or laminated materials.

In this case, fine tuning some of the above values will help reduce the chances of the material cracking or delaminating during a pierce.

Scribe: Delay after nozzle fires before moving

The number of seconds to wait after turning on the water pump before moving the nozzle when scribing. Scribing does not use any abrasive, so the delay is intended to allow the water to reach a reasonable pressure. Because scribing is not a precision machining mode, the water pump does not need to reach its full pressure, so this value is typically lower than the value used for piercing.

Water Only: Delay after nozzle fires before moving

The number of seconds to wait after water begins flowing before moving the nozzle when using Water Only cutting.

Traverse: Seconds to wait after shutdown before traverse

The number of seconds to wait after water stops flowing before moving the nozzle for a traverse. This allows the water time to lose pressure. If this value is too low, the surface of the part may be marred while moving the nozzle.

Other: Pump warm up delay

The number of seconds to wait after turning on the water pump when making this part.

Pump warm up delay

Delay between turning on the high pressure pump and starting to pierce. The pump needs some time to get up to speed and ramping up pressure before it can effectively pierce or cut.

Pump warm up delay before first move

Delay between turning on the high pressure pump and starting to pierce only at the very beginning of the part to allow for initialization of the pump and ramping up pressure.

Water pumps typically need a few more seconds to reach full pressure when they are first turned on.

Print settings

![]() Click the Print icon at the bottom of the dialog to print out a screenshot of the current dialog. This is useful for keeping a record of the settings.

Click the Print icon at the bottom of the dialog to print out a screenshot of the current dialog. This is useful for keeping a record of the settings.

You can take a screenshot of any window in Microsoft Windows by clicking on the desired window to activate it and then pressing Alt+PrintScreen. This copies the window's image to the clipboard. From there, you can paste the image into another program, such as the utility “WordPad” that comes with Windows. This can be useful when documenting settings and other screen content.