![]()

![]()

________________________________________

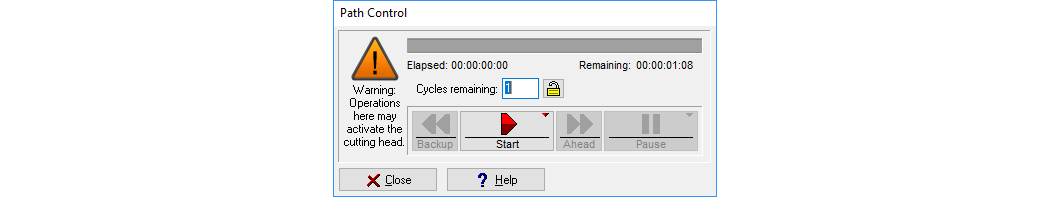

The Path Control functions appear when you press the "Begin Machining" button

They control the cutting head as it machines a part. Note that machining will not begin until is clicked.

Use Path Control to start and stop machining

The progress bar shows the percent complete in terms of distance not time. If you want to know the estimated time remaining, then look at the "Remaining" display.

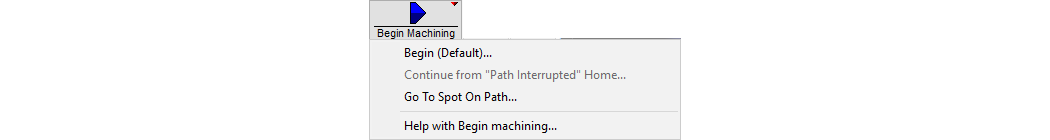

Right-click on the Begin Machining button, and the following menu appears.

[ ]

]

The Begin Machining right-click menu.

Begin (Default)…

The standard Path Control dialog appears.

Continue from "Path Interrupted" Home…

The Path Control appears, ready to continue at the location where the machining head was paused. (If there was no pause during the making of the last part, this option is not available.) The machining head will not move until Continue is clicked.

Go to Spot on Path…

After selecting this option, click on a spot on the tool path where the machining head should to go. The machining head will traverse directly there (it does not follow the tool path--make sure that the machining head will not strike any fixtures when it moves).

GlobalMAX can go through a "dry run" of a part that goes through all the motions of making the part without any water or abrasive.

Press to begin making the part. A small white cross will appear on the drawing showing the current location of the machining head.

Pressing Start will activate the high-pressure water pump and nozzle. Make sure that the machining head is free and able to move without obstruction. Make sure that the nozzle is pointed safely into the catching tank, and that no body parts are in front of the nozzle.

The GlobalMAX can always be paused by clicking the Pause button to pause machining at the current location. Press Start again, and machining will resume.

Pausing the GlobalMAX may result in a minor surface blemish at that location on your part. To avoid this, consider using "Pause at next traverse".

If MAKE is minimized, or there is another application that has the focus, then you may not be able to easily reach the Pause button with the mouse. You should get in the habit of using the external "Pause" button on the controller for pausing the machine.

You can also use the Space bar on the keyboard to pause the machine. You should, however, consider this unreliable, because if another application (such as Microsoft Word) has the focus, then the Space bar will not pause the machine, but will instead insert spaces into your Word document. Again, you should get in the habit of using the external Pause button on the controller for pausing the machine.

Make more than one copy of a part by changing the Cycles Remaining number. It will start out at one (making one copy of the part). If this is set to more than one, after finishing the first copy, the GlobalMAX will immediately begin making the second copy. During machining, this number is updated to show the number of cycles remaining to be made. (Since a drawing may consist of several parts, MAKE refers to it as "cycles.")

The GlobalMAX will begin making the next copy exactly where it ended making the first copy. Make sure that the last traverse for the part leaves the machining head where it can begin making the next copy without cutting into the first copy.

Ten seconds after the machining dialog appears, the Cycles Remaining box will lock itself to prevent accidental changes. If you want to change it, you will need to click on the lock icon next to the number.

When the Path Control is showing, click on the green arrows with either the left (move quickly) or right (move slowly) mouse buttons to move forward and backward along the tool path.