![]()

________________________________________

A nozzle path is used by the ProtoMAX when machining a part. The nozzle path must be one continuous path, although the abrasive jet can be turned off for during sections of the path by using the Quality of traverse.

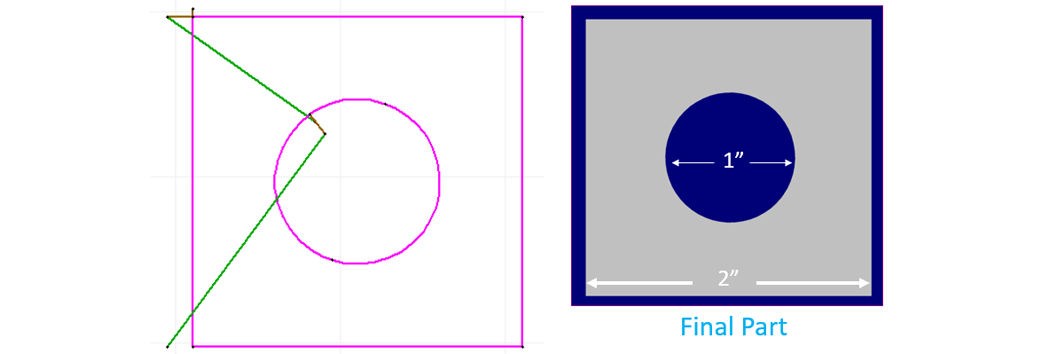

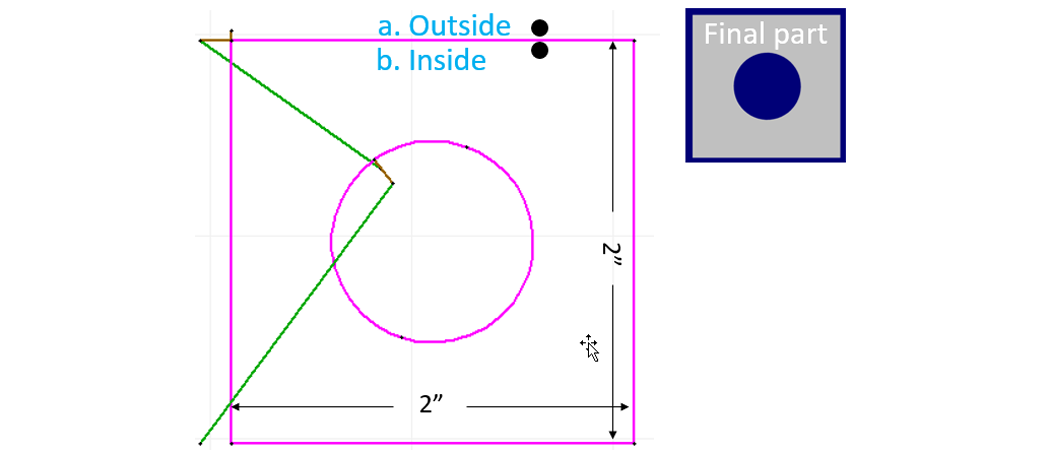

Sample Drawing requiring that a nozzle path be added to cut the part

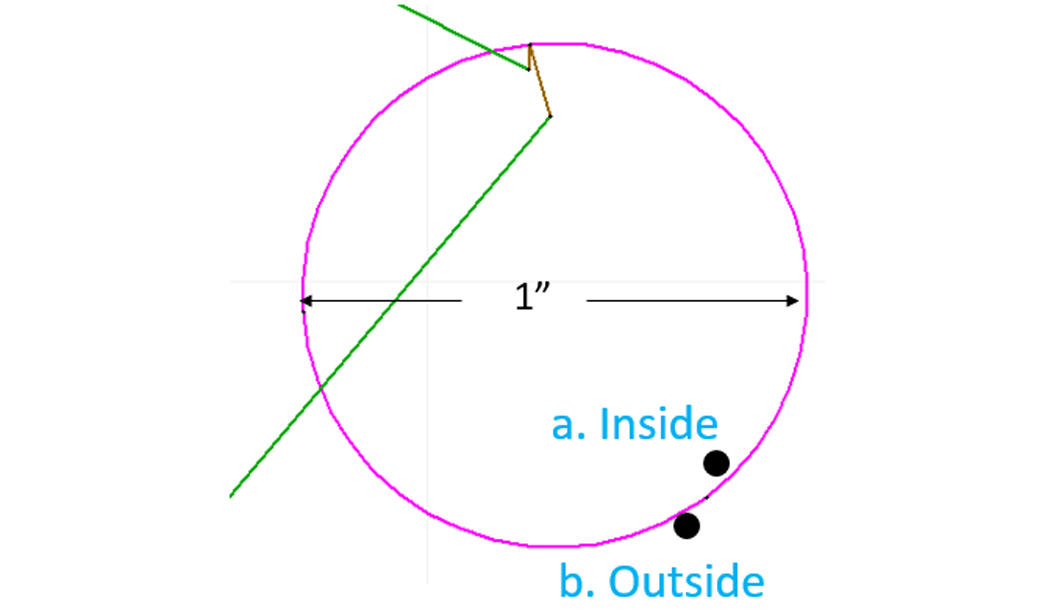

Question: Looking at the circle below, which side do we want the nozzle to cut on? Inside or outside the circle?

Answer:Cut on the inside to maintain the hole diameter at 1 in.

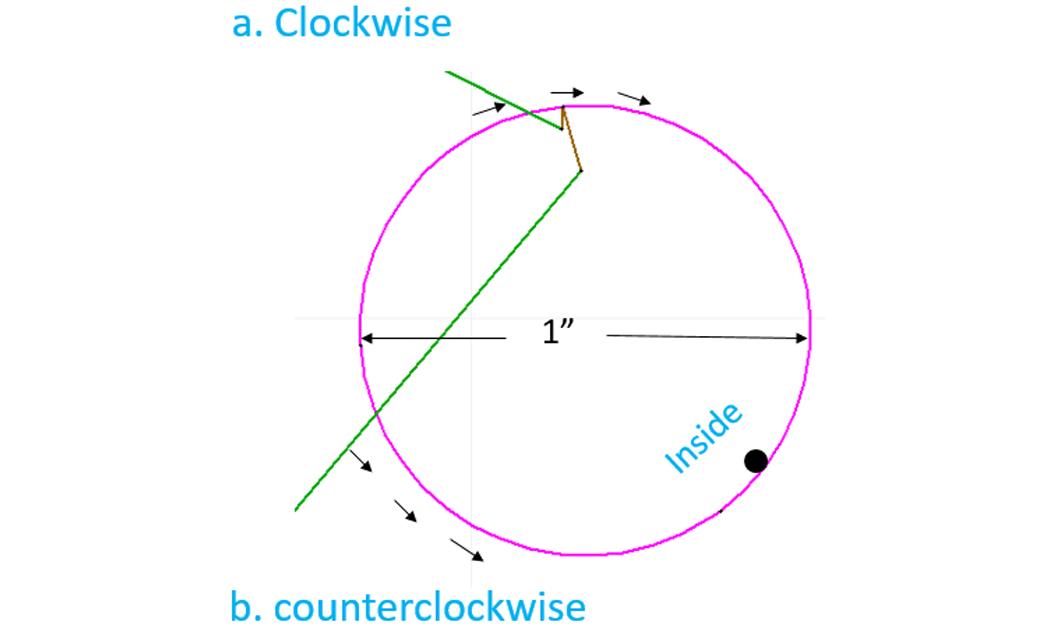

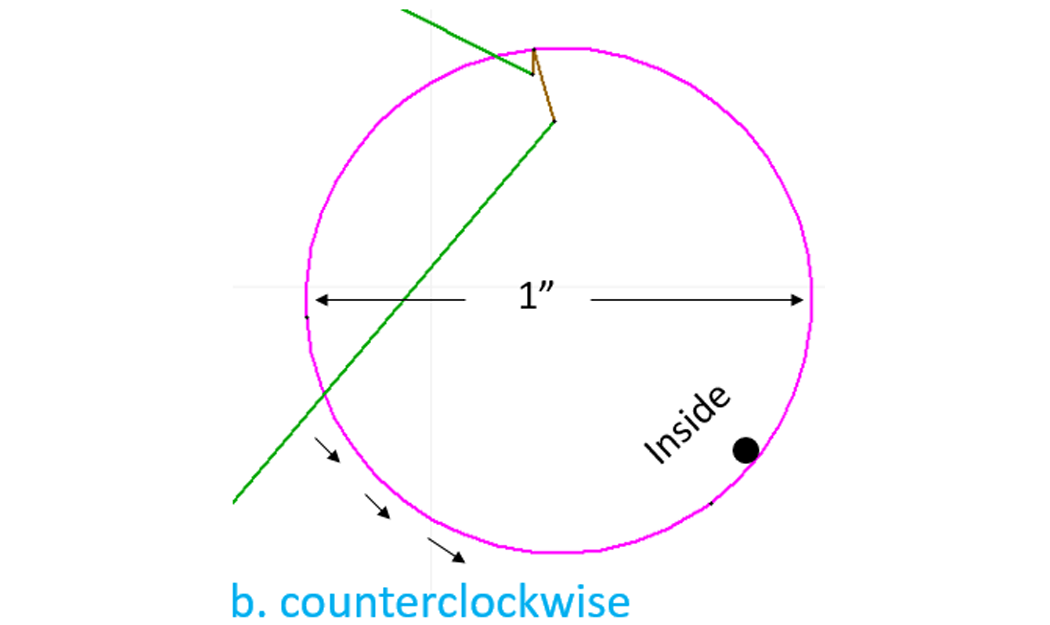

Question: Which direction should the nozzle travel if we want it to cut inside the circle, knowing it will cut to the left of our line? Clockwise or counterclockwise?

Answer: Travel the counterclockwise direction so it cuts to the inside of the internal geometry.

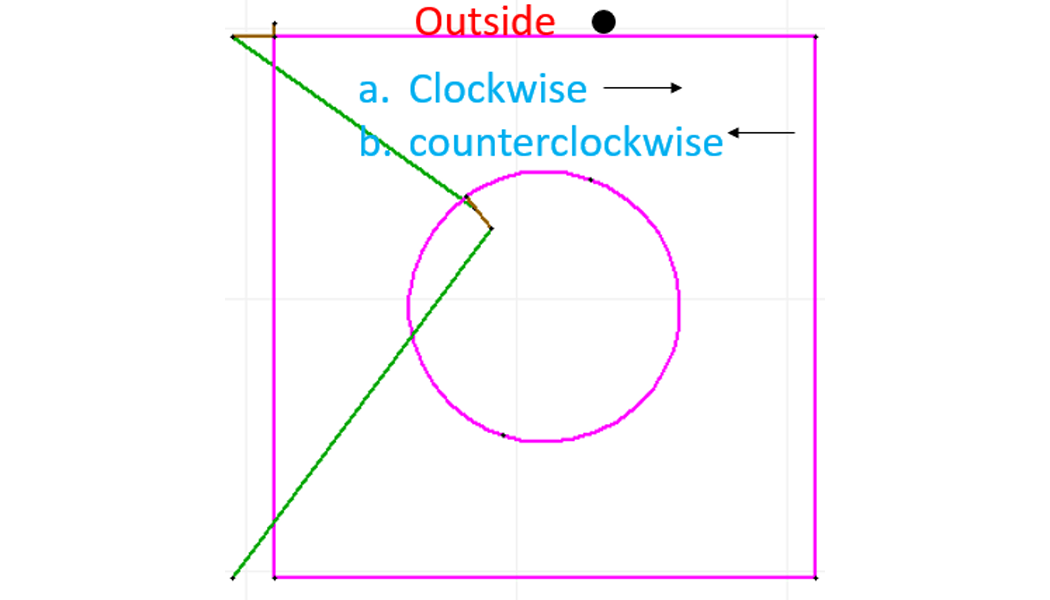

Question: Which side of the external geometry (the box part below ) do we want the nozzle to cut if we want to maintain our part dimension as drawn? Outside or inside?

Answer: We want to cut on the outside of the box

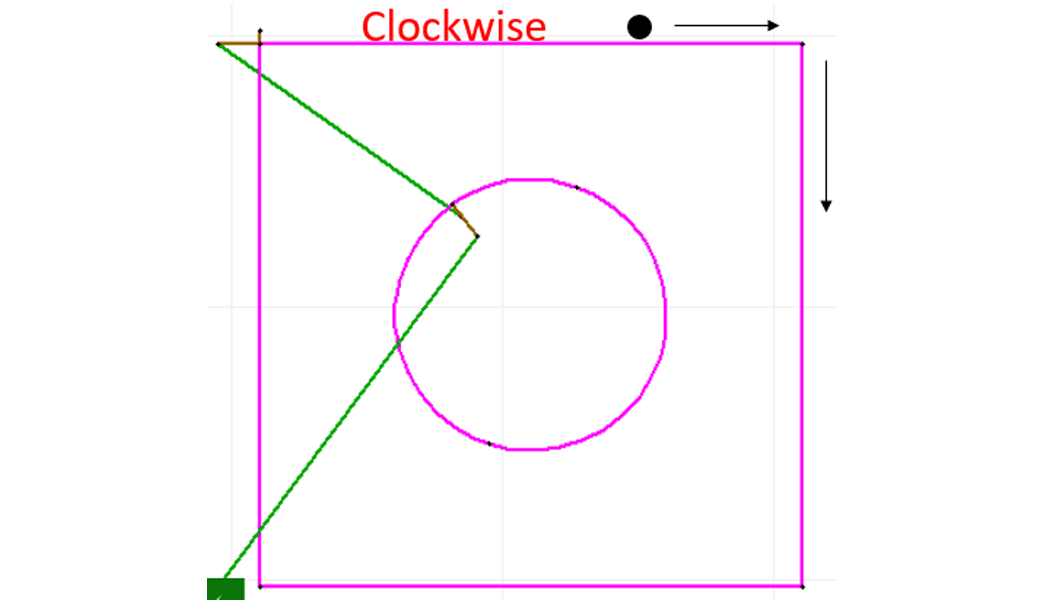

Question: Which direction does the nozzle need to travel to cut on the outside of our box? Clockwise or counterclockwise?

Answer: We want the nozzle to travel in the clockwise direction on external geometry so the kerf is on the left, or outside the geometry:

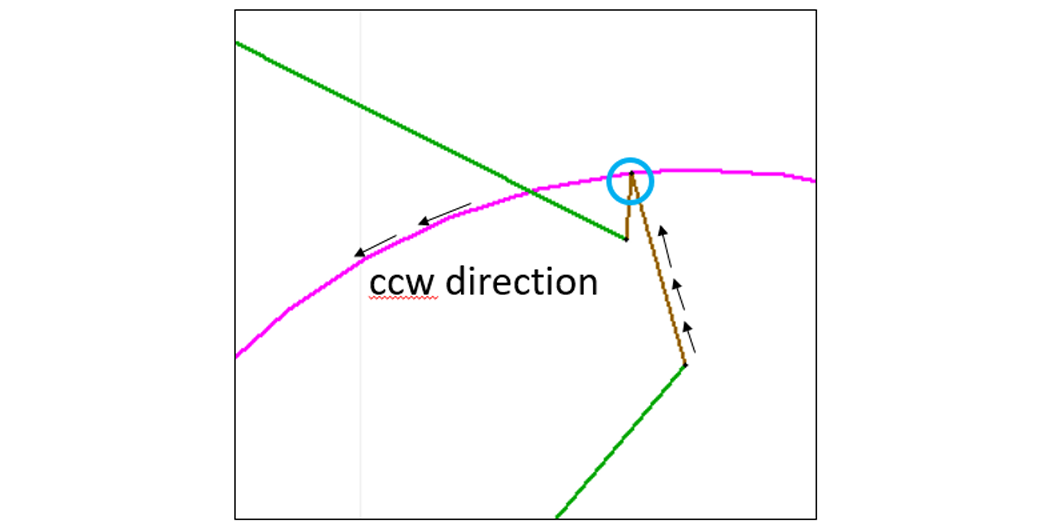

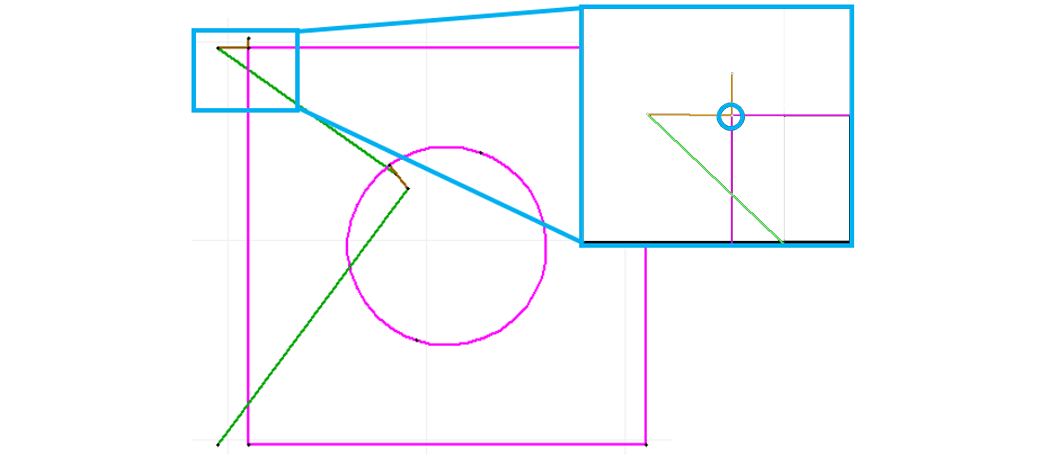

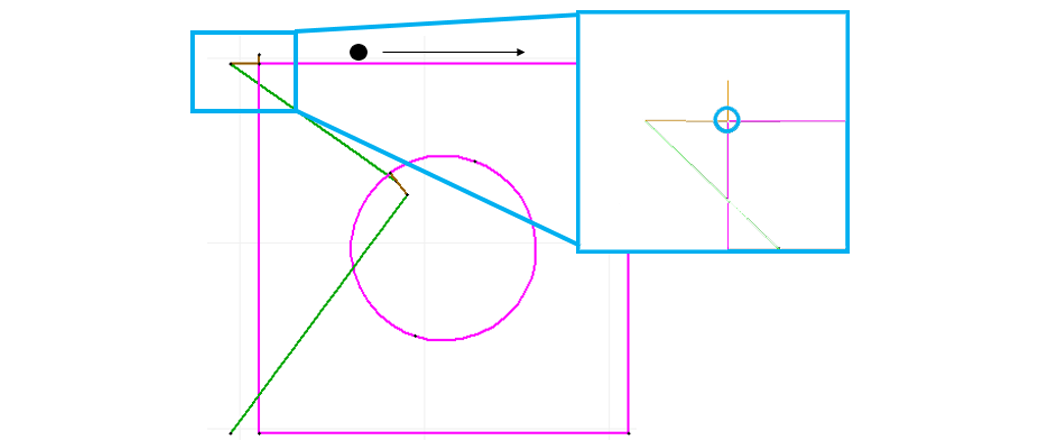

Question: Which direction will the nozzle travel when it reaches the end-point of the lead in for the following example?

Answer: The nozzle will continue to go straight when it reaches the end-point of the lead in in this drawing because it is the least sharp angle or turn to follow:

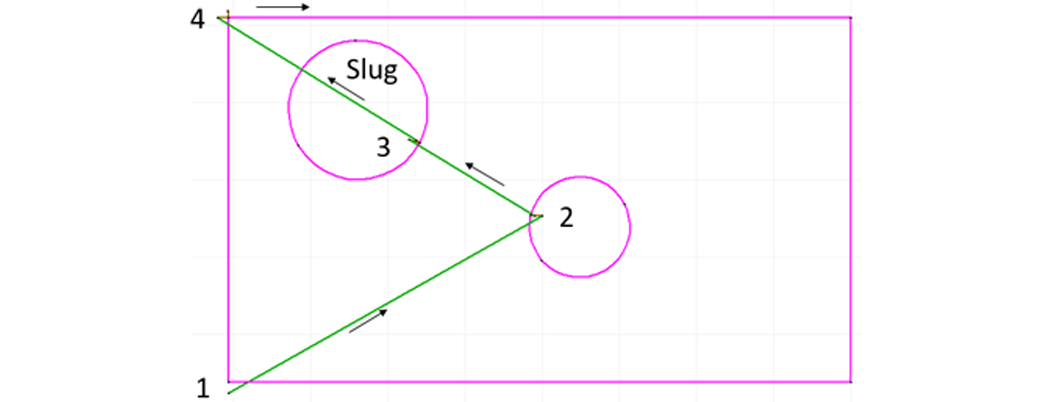

Avoid traveling over something already cut:

To avoid a potential collision with the slug: