![]()

________________________________________

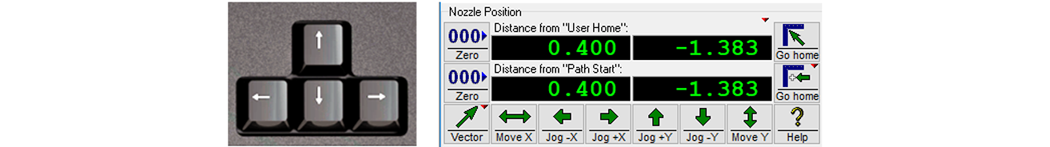

1. Move the nozzle to a location that will not interfere when loading the material on the cutting deck.

- Ensure nozzle is raised sufficiently to pass above and not strike anything in its path.

- Use the keyboard arrow keys or click the nozzle position buttons (such as Move X and Move Y) to control nozzle movement.

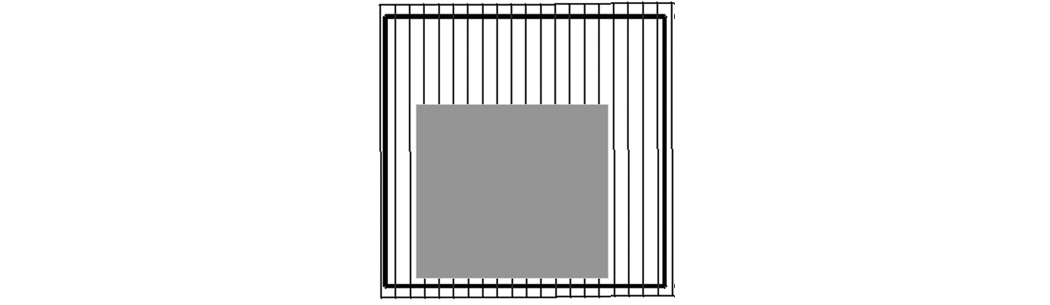

2. Place material on the cutting deck, ensuring that it is:

- Within the nozzle's cutting area

- Accessible to the operator

- Laying flat on the cutting slats

- Free of any obstructions that the nozzle could strike

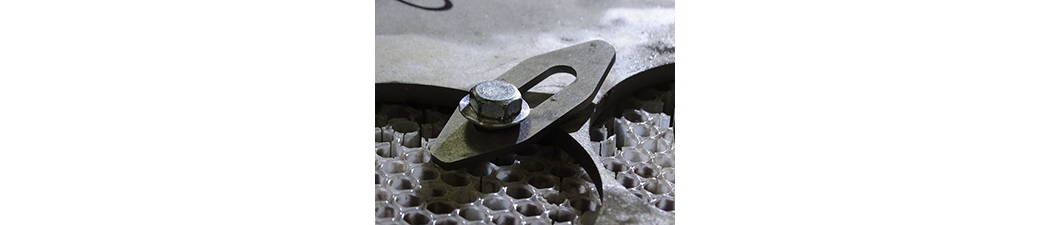

- Using sacrificial material (such as waterjet brick) when applicable

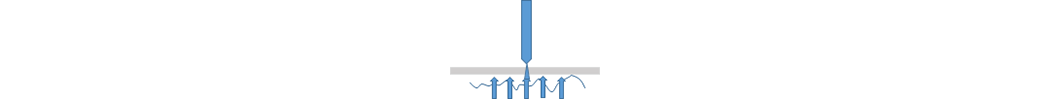

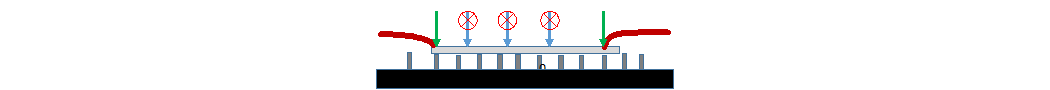

It is important that your material be properly secured, or "fixtured," when using the ProtoMAX. The abrasive jet stream is very powerful, and the force it exerts can push up on the material and move it. If the material moves during machining, the part will not be precise and may be ruined.

Material must be securely fixed to the cutting table, preventing it from moving, vibrating, floating, tipping, or falling into the tank.

NOTICE

Insufficient clamping may cause inaccuracies in finished parts.

Following are some best practices for securing material in the cutting deck, including tips for working with thin material, and using sacrificial material for preventing damage.

Securing thin material for waterjet machining requires extra care. The jet stream causes turbulence and the force under the material is sufficient enough to cause unsecured material to move up or shift. When this happens, the material can raise and hit the mixing tube in the nozzle, causing the nozzle to clog.

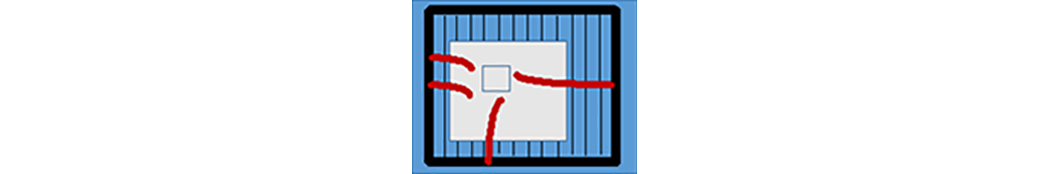

More secure

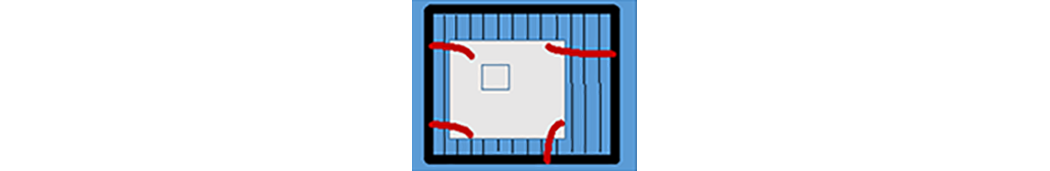

Less secure

Use sacrificial material to stabilize thin material, or to prevent frosting on the part.

The Micro Clamp Material Holding Kit provides additional options for holding and securing material to the slat deck or the polymer cutting deck.