________________________________________

Scribe

A type of quality designed to inscribe soft materials

Scribe is a type of Quality. It is intended to not use any abrasive for entities with a Quality of Scribe. Scribe is intended to be used to inscribe part numbers or designs on soft material.

For Scribe mode on a GlobalMAX, either remove the abrasive feed tube from the nozzle, or use a water only nozzle.

For Scribe mode on a GlobalMAX, either remove the abrasive feed tube from the nozzle, or use a water only nozzle.

The feed rate of the abrasive nozzle for scribe is set when you MAKE your part. OMAX detects any scribe entities in your tool path. Enter the feed rate at which to scribe for each. The slower the abrasive jet nozzle, the deeper the cut made by Scribe will be.

The depth of the cut also depends on the material. Also, because GlobalMAX must decelerate and accelerate at corners, the scribe will be deeper there.

Scribe is generally not effective with harder materials, such as steel. For these materials, Etch may be more appropriate.

Scribe is useful for marking aluminum, copper, and other soft materials.

Scribe is also useful to replace rapid traverse moves when machining hard materials. This can reduce the number of on/off cycles on the high-pressure pump resulting in increased speed to make the part, and reduced wear and tear on the pump. In this case, enter the fastest speed for scribe entities. This is not necessary for intensifier pumps or pumps equipped with a dual on/off valve.

Tip

See Traverse with the pump on for information on using Scribe to greatly speed up the cutting of parts having lots of on/off transitions.

Scribe vs. Etch

Scribe vs. Etch

- Scribe uses only water.

- Etch uses abrasive as well as water.

Scribe vs. Water Only

- Both Scribe and Water Only use only water, with no abrasive.

- Both Scribe and Water Only show up as varying shades of blue when previewed in MAKE.

- With Scribe, the abrasive jet nozzle is centered on the tool path.

- With Water Only Quality, the tool path is offset, so that the dimensions of the finished piece exactly match the drawing. Water Only is intended to be used for making parts from soft materials, such as foam and sponge.

- Scribe can also be used for machining providing a quick way to cut soft materials when offsetting the tool path is not important. For example, when making a muff for the OMAX, either Scribe or Water Only may be used.

Scribe Tips

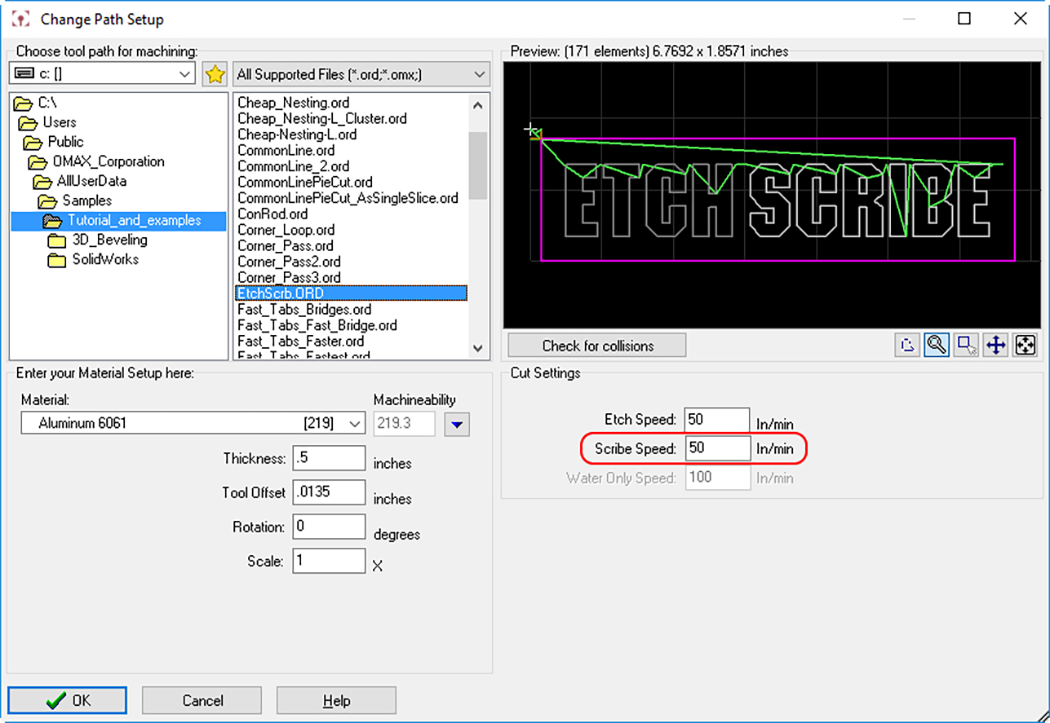

- Adjust the overall Scribe speed in the Change Path Setup dialog.

In the Change Path Setup dialog, select a part that has Quality of Scribe in it. When this is done, the Scribe Speed box is enabled allowing you to adjust the speed of all Scribe Quality entities in the path.

The maximum Scribe Speed that can be entered depends entirely on what maximum X/Y for the machine is allowed. If a value is entered that is above the maximum X/Y speed of the machine, the edit box changes to yellow indicating an error. This setting is in the Advanced/Administrator setup where it is advised that it only be changed under the direction of OMAX Customer Service.

- Use XData if different Scribe Speeds are needed within one drawing. If you would like to have different Scribe speeds for one part, the speed assignments can be made within LAYOUT by selecting the Scribe entity and using “[014]: Force absolute speed” to change the speed for that particular entity.

- Avoid pitting at the start of the scribe with "tangential scribe on the fly." If the "delay after nozzle fires before moving" setting in the "Event and Relay Setup" dialog is set to zero for the scribe, and the transition between the proceeding traverse and the scribe is tangent, then the scribe will "Scribe on the fly" without slowing down to a stop at the start of the scribe. This can eliminate the small pit that may otherwise form at the start of the scribe in certain hardware setups, and is a very good way to help improve the results. If this behavior is not desired, then either use a small delay, or don't come in tangentially.

- Avoid pitting at corners by using lower pressure. Using lower pressure allows scribing at slower speeds, which means that the machine does not have to slow down as much at corners, reducing the dwelling at corners and providing a nice even scribe.

- Avoid pitting at corners by avoiding sharp corners. The machine has to slow down for sharp corners in order to prevent vibrations and machine wear. Slowing for the corners causes dwell at the corners, causing the jet to dig in deeper. To avoid this, consider rounding the corners with a small fillet.

- For a more even scribe, clear out residual abrasive and remove abrasive tube. If there has been abrasive cutting or etching prior to the scribe, the nozzle may have several seconds worth of residual abrasive left in the lines causing the start of scribes to be slightly deeper than the rest. To clear out the nozzle of abrasive, consider firing the nozzle in water only or scribe mode on a section of scrap material for a few seconds with the abrasive tube removed, or using a Water Only nozzle.