Etch is a type of quality designed to mark material without piercing it.

While Etch uses abrasive and water like cutting, the nozzle moves much faster across the material, marking the surface without piercing it. Etching works best on metals. Etching occurs at the top speed of the ProtoMAX, 100 in. per minute (2540 mm per minute). Advanced users can adjust to a slower speed using XData.

Some ways to use the Etching feature:

Consistently produce good results

Inconsistent results

These applications may need some experimentation.

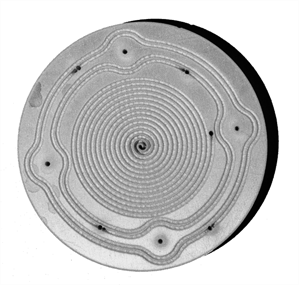

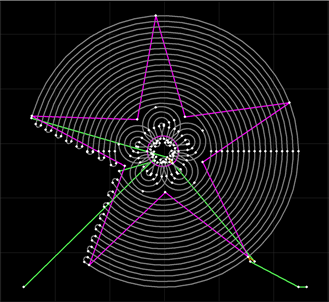

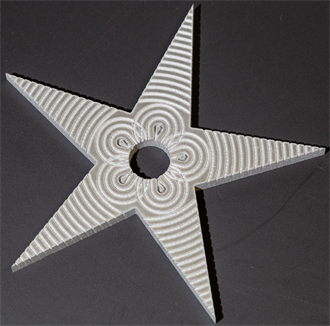

This piece shows how Etch can be used for different functions.

Abrasive waterjet etching is not going to produce equivalent results to other processes such as milling, laser, or chemical etching. For many part marking purposes, a laser or other tools may often be a better choice. However, the waterjet produces results that have their own place, and is often quite useful for creating practical or artistic parts.

While metal is recommended and has the least amount of risk, non-metal materials can sometimes be etched with a bit of experimentation. This table shows materials ranging from best to not recommended for waterjet etching.

| Etching | Material | Notes |

|---|---|---|

| Best | Metals | For a cleaner etch and less noticeable corner digging, use a hard metal like steel rather than a soft metal like aluminum. |

| Varying results | Stone | Stone can be etched in some cases. In other cases, it will chip or blast away into fragments. |

| Glass and other brittle materials | See Etching on brittle materials. | |

| Not recommended | Wood | Wood tends to cut or split. |

| Wood Laminates and composites | This type of material does not etch well. |

An abrasive waterjet can do etching in an unrefined manner, where results can vary depending on many factors. It is important to know ahead of time what kind of results to expect, and plan accordingly. Often, some experimentation is required. Below are tips on how to make the most of etching on your ProtoMAX.

Abrasive type also makes a difference. For example, the Barton 85 HPX will do a cleaner job than the 80 HPX, a faster cutting, more aggressive abrasive.

Some pitting will occur wherever the jet stream turns on or off. When the jet stream turns on and the pump stabilizes, it will dig into the material and create a pit or hole the diameter of the jet stream. Likewise, when the jet stream turns off, a similar pit will result as the pump cools down in preparation for traversing. This is a normal and expected behavior on ProtoMAX machines that one must consider when designing parts that contain Etch.

It is recommended that you start your etch away from what will become the part to avoid pitting that is not part of the design. While you certainly can start your etch in the part itself, please note that pits at the start and end of the etch can be so severe that they drill completely through the material.

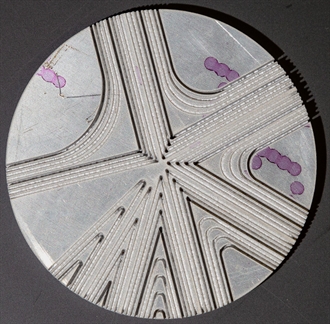

Because the machine cannot take sharp corners with infinite accelerations, it needs to slow down at corners for any entity in the tool path. This prevents excessive machine vibrations or motor faulting. As the machine slows down for corners and tight radii, the jet will dig deeper into the material, resulting in pits at corners.

Use radii instead of sharp corners to avoid pitting in corners where the machine would otherwise have to slow down. The larger the radius, the less the machine has to slow down. So the more even the etch will be.

This coin shows sharp corners as well as large radii. Notice the pitting in sharp corners.

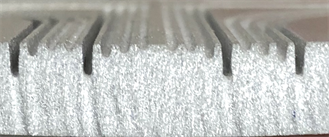

Be aware of increased noise and abrasive splash. The splash will cake the inside of your machine over time, and may accelerate the wear of all machine components, including fogging and sandblasting the clear ProtoMAX lid.

To minimize accelerated wear on the machine:

Lots of on/off cycles can cause accelerated wear on high pressure components.

Too many small etch entities may cause the nozzle to clog.

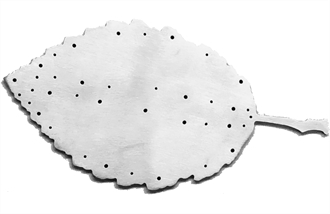

The waterjet is an extremely powerful process. As such, etching on thin or soft materials can often result in cutting all the way through, ruining a part.

Unless the desired result is a deep hole or possibly a hole through the part, avoid using etch on entities smaller than 0.06 in. (1.52 mm). The beginning and ending will likely connect, cutting all the way through the part.

Aluminum etched leaf: The jet stream pierces through because this material is too thin.

Etching on brittle materials such as glass produces varying results. For example, the force of the jet stream might cause the material to crack or break. However, this type of material can etch well if it is thicker, more pliable, and well-supported. While you may not get a perfect result on the first try, we encourage you to experiment.

This five-pointed star shows examples of several tips mentioned above.

Sample etch files can be found in ProtoMAXLAYOUT in Samples\Tutorial_and_examples\Etch_.... Did you create something cool? Post it to the ProtoMAX Community!