________________________________________

Etch Tips

The Etch Quality is primarily used to mark a surface with part numbers or to do other simple etching. With a little work and some practice, however, Etch can also be used to remove material, create relief effects, and even create engravings.

Etching becomes increasingly difficult or impossible when working with thin or soft materials. In thin materials, the jet is likely to cut all the way through. In soft materials, the jet will also likely cut all the way through, or dig deep into the corners of the drawing entities as the machine slows down.

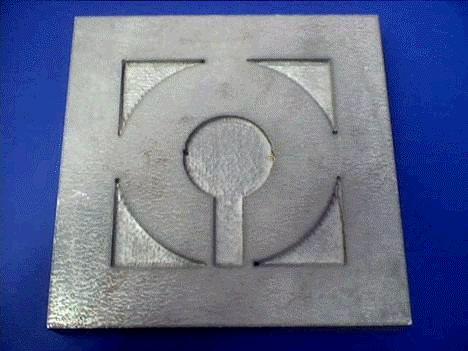

Part created using Etch Quality

The main issue with doing intricate work is usually that the nozzle has to slow down for corners when using Etch (not for any cutting model, but instead to accelerate and decelerate the cutting head). Below are some tips for effectively using Etch for intricate work:

- Do the etching on a smaller machine that can accelerate harder, and it won't slow down as much. This will reduce the excessive material removed in the corners.

- Do the etching at a lower pressure and reduce the abrasive feed rate. Also slow the machine down more to get the desired etch depth. When everything is moving slower, the slow down in the corners will be less relative to the rest of the part, resulting in less excessive material removed.

- Vary the speed of multiple etches in the same path with XData. If you have the need for different speeds of etching (for example, to have different depths), consider using XData to override the speeds with an absolute speed.

- When etching brittle material such as glass or granite, reducing the pressure is required to prevent cracking. Setting the pump to 20 KSI (140,000 kPa) or lower is recommended. Even 30 KSI (200,000 kPa) is too much pressure.

- Avoid sharp corners, and the slow down will be less—you won't dig so much into the material.

- By etching into a hard metal-like steel, instead of a soft metal like aluminum, the etching will be much cleaner, and again the corner digging will be less noticeable.

- Anywhere the etch lines cross each other will be etched twice as deep.

- As you etch, the jet will lag, just as in cutting. Imagine that you are etching a square shape to a depth of 0.5 in. (1.3 cm). Seen three-dimensionally, you have machined out an area that looks like a box, with the bottom of the box skewed opposite of the direction of the jet. This is yet another reason to use lower pressure and slow the jet down. By etching over the same area multiple times, using patterns of opposite directions, this effect can be canceled out.

- For some materials, consider cutting a "mask" on the machine, then using the mask in conjunction with a sand blaster to remove the material on the final part.